If you are interested in products and services related to the research phase in this field, please contact for further inquiries.

Functional orthopedic compression textiles represent a critical segment of medical devices, offering targeted support and therapeutic benefits for a wide range of medical conditions. This article provides an in-depth exploration of the classification, structure, and construction of these textiles, highlighting their applications and the scientific principles that underpin their efficacy.

Introduction to Functional Orthopedic Compression Textiles

Medical textiles have long been recognized for their critical role in healthcare, encompassing everything from implantable materials to hygiene products. Among these, compression textiles stand out for their ability to exert controlled pressure on the body, promoting blood circulation, reducing swelling, and providing support to injured or weakened limbs. The use of compression garments has significantly increased since the 1970s, initially for treating burns and post-surgical conditions, but now extending to a broader spectrum of medical applications, including venous and lymphatic disorders, bone and muscle injuries, and even sports medicine.

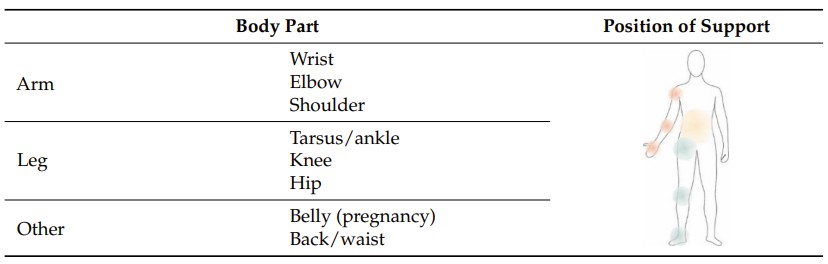

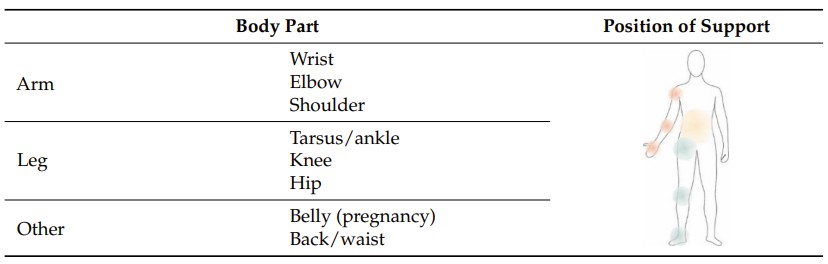

Fig.1 Classification of orthopaedic supports according to the position on the body. (Mikucioniene D., et al., 2024)

Fig.1 Classification of orthopaedic supports according to the position on the body. (Mikucioniene D., et al., 2024)

Classification of Compression Garments

Compression garments can be broadly categorized based on their intended application and the part of the body they target. For instance, medical orthopedic compression supports are designed for specific body parts such as knees, ankles, elbows, and shoulders, addressing issues like joint instability, ligament injuries, and post-operative care. Other types include medical compression stockings for vascular diseases, post-operative compression stockings, compression bandages, and garments for body formation.

| Group |

Purpose |

| Medical Orthopedic Compression Supports |

Prevention, functional or rehabilitation support for specific body parts |

| Medical Compression Stockings |

Prevention and treatment of vascular diseases |

| Post-Operative Compression Stockings |

Compression therapy after leg operations |

| Compression Bandages |

Treatment for venous diseases, post-trauma care, and wound management |

| Compression Garments for Body Formation |

Improving body shape and appearance |

Specific Requirements for Compression Garments

The effectiveness of compression garments hinges on their ability to meet specific requirements. These include matching individual body dimensions, ensuring appropriate physical and chemical properties, maintaining shape and functionality under biological conditions, and avoiding skin irritation or discomfort. For orthopedic compression products, additional criteria such as accurate limb measurement, biomechanical assessment, and long-term durability are crucial.

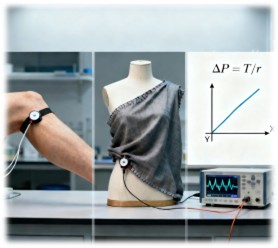

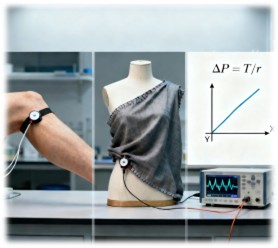

Compression Measurement Systems

Accurate measurement of compression is essential for the efficacy of these garments. There are three primary methods for determining compression: direct in vivo measurement, indirect in vitro measurement, and control of treatment therapies. Direct in vivo methods involve measuring pressure directly on the affected limb using devices like the SIGG-test or PicoPress. Indirect in vitro methods measure the stretching behavior of the fabric using specialized mannequins and sensors, adhering to standards like the German RAL-GZ 387/1 or the British BS 6612. Theoretical methods use Laplace's Law to calculate compression based on tensile force and fabric area.

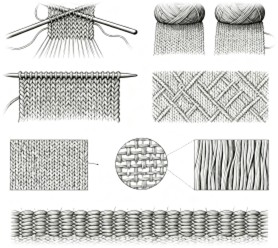

Structure and Construction of Compression Textiles

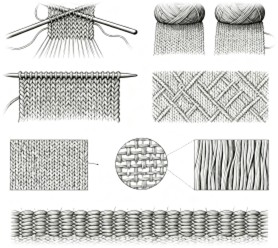

Compression textiles are typically made by knitting at least two types of yarns: a ground yarn for stiffness and thickness, and an elastomeric yarn for generating compression. The choice of knitting pattern and the type of yarns used significantly influence the final product's properties. For example, polyamide yarns are popular for their high elongation and abrasion resistance, while polyester microfibers offer strength, flexibility, and good capillarity.

Additional Functionalities

Modern compression textiles often incorporate additional functionalities to enhance their therapeutic benefits. These can include antimicrobial properties, thermal therapy, and even electro-conductive yarns for heating elements. The integration of these features requires careful consideration of material properties and manufacturing techniques to ensure both comfort and functionality.

Challenges and Future Directions

Despite the advancements in compression textile technology, several challenges remain. The lack of a uniform global standard for compression levels complicates the design and evaluation of these products. Additionally, maintaining compression efficacy over time, especially considering stress relaxation, is a significant concern. Future research should focus on developing standardized measurement techniques, exploring new materials with enhanced properties, and improving the overall comfort and compliance of compression garments.

Conclusion

Functional orthopedic compression textiles represent a critical advancement in medical therapy, offering targeted support and treatment for a variety of conditions. As research continues to evolve, the potential for these textiles to improve patient outcomes and quality of life remains promising. Continued innovation in material science, manufacturing techniques, and clinical application will further enhance the efficacy and comfort of these essential medical devices.

If you have related needs, please feel free to contact us for more information or product support.

Reference

- Mikucioniene, Daiva, et al. "Classification, Structure and Construction of functional orthopaedic compression knits for medical application: a review." Applied Sciences 14.11 (2024): 4486.

This article is for research use only. Do not use in any diagnostic or therapeutic application.

Fig.1 Classification of orthopaedic supports according to the position on the body. (Mikucioniene D., et al., 2024)

Fig.1 Classification of orthopaedic supports according to the position on the body. (Mikucioniene D., et al., 2024)