If you are interested in products and services related to the research phase in this field, please contact for further inquiries.

Industrial exoskeletons represent a transformative innovation in the realm of workplace safety and efficiency. These wearable devices are designed to augment human capabilities, providing additional support and reducing the physical strain associated with demanding manual tasks. As industries continue to grapple with the challenges of worker safety and productivity, exoskeletons emerge as a promising solution, blending advanced engineering with ergonomic design to create a safer and more efficient work environment.

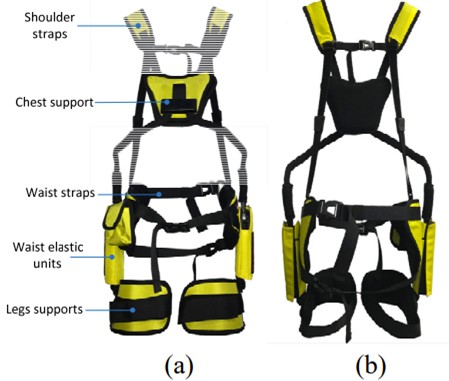

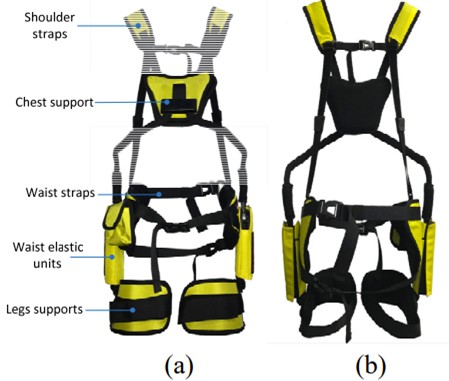

Fig.1 The structure diagram of IPWE used in the tests consisting of a shoulder straps, chest support, waist straps, waist elastic units and leg supports, showed in two views: (a) front view; (b) rearview. (Zeng D., et al., 2021)

Fig.1 The structure diagram of IPWE used in the tests consisting of a shoulder straps, chest support, waist straps, waist elastic units and leg supports, showed in two views: (a) front view; (b) rearview. (Zeng D., et al., 2021)

The Prevalence of Low Back Pain in Industrial Settings

Low back pain (LBP) is a pervasive issue in industries that require frequent manual handling, such as construction, agriculture, mining, and warehousing. Studies indicate that up to 80% of adults will experience LBP at some point in their lives, with 4-5% suffering from acute LBP annually. The economic impact is substantial, with LBP being a leading cause of restricted activity, absenteeism, and increased compensation costs for businesses. The development of exoskeletons aims to mitigate these risks by providing mechanical support, reducing muscle strain, and enhancing overall worker safety.

The Industrial Passive Waist-assistant Exoskeleton (IPWE)

The IPWE is a pioneering example of wearable technology designed to address the challenges of manual labor. This passive exoskeleton leverages elastic elements to simulate human muscles, providing additional support and reducing the strain on the lower back. The device consists of a chest support, waist elastic units, leg supports, and several webbing components, all working together to distribute the load more evenly across the body. The IPWE operates on a simple yet effective principle: by aligning elastic elements parallel to the erector spinae muscles and leg muscles, it provides mechanical assistance during bending and lifting movements.

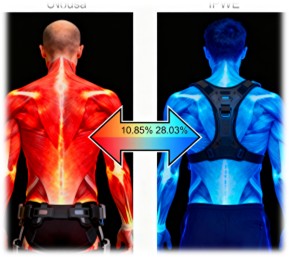

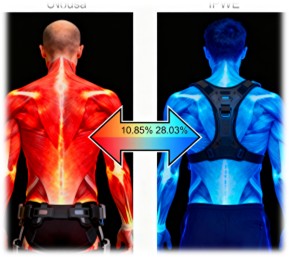

Testing the Effectiveness of the IPWE

A comprehensive study was conducted to evaluate the impact of the IPWE on muscle activity and fatigue. The study involved eight healthy subjects performing simulated lifting tasks with and without the exoskeleton. The results showed a significant reduction in muscle activity in the lower back, with the RMS amplitude of the thoracic erector spinae (TES) and lumbar erector spinae (LES) muscles decreasing by 10.85% to 28.03%. This reduction suggests that the IPWE effectively alleviates the strain on the lower back muscles, potentially reducing the risk of muscle fatigue and injury.

Oxygen Consumption and Metabolic Impact

The study also measured the oxygen consumption of subjects during the lifting tasks. The results indicated no significant difference in relative oxygen consumption between the conditions with and without the IPWE. This suggests that wearing the exoskeleton does not impose additional metabolic demands, making it a practical solution for repetitive lifting tasks.

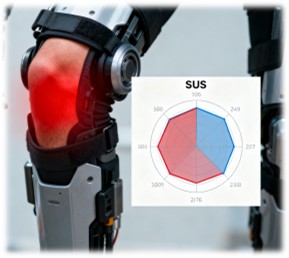

Subjective Perceived Fatigue and Pressure

Participants rated their perceived fatigue using the Borg's Rate of Perceived Exertion Scale (Borg RPE 6-20) and reported increased pressure on the thighs and shoulders when wearing the IPWE. While the increased pressure did not cause significant discomfort, it highlighted the need for design improvements to enhance user comfort. The study also used the System Usability Scale (SUS) to evaluate the overall usability of the exoskeleton, with results indicating that half of the subjects found the IPWE to be acceptable.

Future Directions and Design Improvements

The findings of the study underscore the potential of the IPWE to significantly reduce muscle activity and the risk of low back pain. However, areas for improvement include user comfort and device weight. Future research and development should focus on optimizing the design of the IPWE to enhance its usability and acceptance among workers. Long-term studies involving real-world industrial applications would provide valuable insights into the device's practical effectiveness and potential impact on worker health and productivity.

Conclusion

The Industrial Passive Waist-assistant Exoskeleton (IPWE) represents a significant advancement in wearable technology aimed at improving workplace safety and reducing the risk of low back pain. The study's findings demonstrate the IPWE's effectiveness in reducing muscle activity in the lower back during manual handling tasks, without significantly impacting oxygen consumption or perceived fatigue. While the device shows promise, areas for improvement, such as user comfort and device weight, must be addressed to enhance its usability and acceptance. As wearable technology continues to evolve, the IPWE and similar exoskeletons could play a crucial role in creating safer and more efficient industrial workplaces.

If you have related needs, please feel free to contact us for more information or product support.

Reference

- Zeng, Dezheng, et al. "The assist performance test of industrial passive waist-assistant exoskeleton on fatigue during a repetitive lifting task." Journal of Physics: Conference Series. Vol. 1748. No. 6. IOP Publishing, 2021.

This article is for research use only. Do not use in any diagnostic or therapeutic application.

Fig.1 The structure diagram of IPWE used in the tests consisting of a shoulder straps, chest support, waist straps, waist elastic units and leg supports, showed in two views: (a) front view; (b) rearview. (Zeng D., et al., 2021)

Fig.1 The structure diagram of IPWE used in the tests consisting of a shoulder straps, chest support, waist straps, waist elastic units and leg supports, showed in two views: (a) front view; (b) rearview. (Zeng D., et al., 2021)