If you are interested in products and services related to the research phase in this field, please contact for further inquiries.

Orthoses, including exoskeletons and fracture fixation devices, are essential tools in orthopedics, designed to support, stabilize, and immobilize limbs, thereby enhancing mobility and improving the quality of life for individuals with locomotion difficulties. Traditional manufacturing methods have long dominated the production of these devices, but they often fall short in terms of personalization and cost-effectiveness. The advent of additive manufacturing (AM), also known as 3D printing, has revolutionized the field by enabling the production of highly personalized orthotic devices at a fraction of the cost and time.

Additive manufacturing creates objects by adding material layer by layer, allowing for the fabrication of complex geometries without the need for tooling. This technology not only minimizes material waste but also reduces assembly requirements and process steps. AM is particularly well-suited for low-volume production and customized products, making it an ideal solution for the orthotics industry.

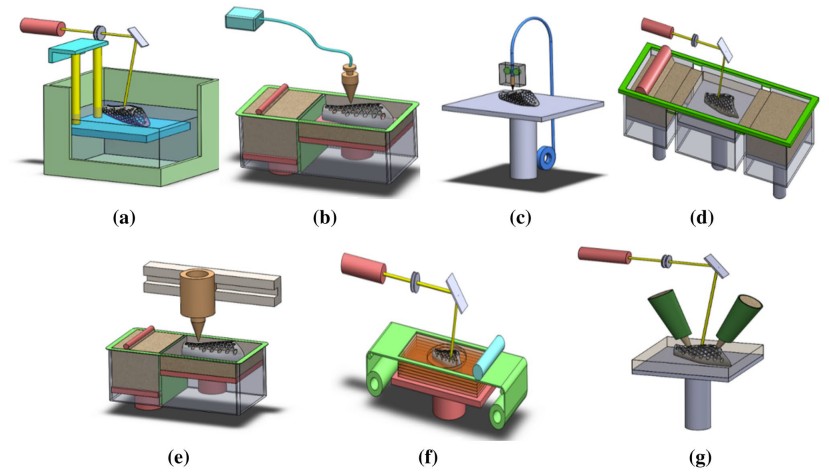

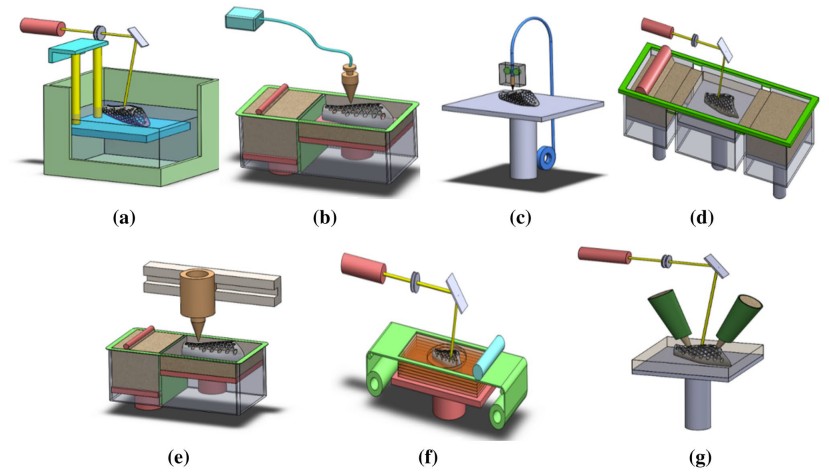

Fig.1 Different additive manufacturing technologies: a vat photo-polymerisation, b material jetting, c material extrusion, d power bed fusion, e binder jetting, f sheet lamination, g direct energy deposition. (Alqahtani M. S., et al., 2020)

Fig.1 Different additive manufacturing technologies: a vat photo-polymerisation, b material jetting, c material extrusion, d power bed fusion, e binder jetting, f sheet lamination, g direct energy deposition. (Alqahtani M. S., et al., 2020)

The Need for Personalized Orthoses

Locomotion problems affect millions of people worldwide, with causes ranging from accidents and falls to age-related diseases. According to the Centre for Disease Control and Prevention, over 17 million adults in the United States alone face such issues. Orthoses are orthopedic devices designed to support, stabilize, and immobilize limbs, helping patients with walking difficulties or those recovering from spinal cord injuries or strokes. These devices can be broadly categorized into two groups: exoskeletons, which enhance human performance, and fracture fixation devices, which immobilize and stabilize fractured bones.

Personalization is key to the effectiveness of orthoses. Devices that are tailored to the specific anatomical characteristics of each patient offer better fit, comfort, and performance. However, traditional manufacturing methods have often made it difficult to achieve this level of customization due to high costs and technological limitations. Additive manufacturing has changed this paradigm by enabling the production of complex, personalized orthoses at a lower cost and with greater efficiency.

Additive Manufacturing Technologies for Orthoses

Several additive manufacturing technologies are used to produce orthoses, each with its own advantages and limitations.

Vat Photo-polymerisation

Vat photo-polymerisation uses photo-curable polymers, which are relatively expensive compared to other polymer-based techniques. This method involves selectively curing a liquid polymer using UV radiation from a laser or lamp. Mavroidis et al. compared AFOs produced through different techniques, including vat photo-polymerisation, and found that the performance of additive manufactured custom-fit AFOs is similar to standard orthoses in terms of controlling the kinematics and kinetics of the ankle.

Material Extrusion

Material extrusion is the most popular additive manufacturing technique due to its low cost and wide range of materials. This process involves selectively dispensing melted material through a nozzle. Patar et al. produced customized dynamic AFOs using Acrylonitrile Butadiene Styrene (ABS), while McDaid et al. designed and produced a robot exoskeleton using Polylactic acid (PLA). These studies demonstrate that material extrusion can produce lightweight, functional orthoses with sufficient strength and stiffness.

Powder Bed Fusion

Powder bed fusion can produce both polymeric and metallic parts by selectively fusing regions of a powder bed using thermal energy. Bhatia and Sharma used this technology to print a robotic suit for a woman paralyzed from the waist down, enabling her to walk and perform daily activities. Pallari et al. investigated the feasibility of using powder bed fusion for custom foot orthoses, showing that 3D-printed orthoses are as effective as currently prescribed ones.

Case Studies and Applications

- Customized External Fixators

The Q-Fixator is a customized external fixation device produced using vat photo-polymerisation. This device, composed of two frames connected by threaded rods and adjustable nuts, provides stability and prevents shear and rotational forces on healing bones. The Q-Fixator has been successfully used to treat tibial fractures, offering advantages such as easy assembly and cleaner X-ray images.

- Lightweight and Functional Orthoses

McDaid et al. designed a robot exoskeleton for lower limb gait training and rehabilitation using PLA. This lightweight device, produced using material extrusion, demonstrates the potential of additive manufacturing to create functional orthoses that are both comfortable and effective. Churchwell et al. replaced an aluminum CNC-machined part with a 3D-printed component for a hip exoskeleton, achieving significant weight reduction and cost savings.

- Complex and Comfortable Designs

Chen et al. used finite element modeling to design and produce AFOs with lower strain during the gait cycle. These orthoses, made from materials like PC-ABS and ULTEM, show the potential of additive manufacturing to create devices with improved mechanical properties. Blaya et al. designed splints for Achilles tendon injuries using advanced manufacturing techniques, combining comfort and resistance in the materials used.

Challenges and Future Directions

Despite the numerous advantages of additive manufacturing in orthotics, several challenges remain. These include the limited working volume of most additive manufacturing machines, the need for assembly of large-scale devices, and the complexity of embedding sensors and actuators in active exoskeletons. Additionally, the design of orthoses must consider the specific characteristics and constraints of each additive manufacturing technique.

- Overcoming Limitations

Future research should focus on developing larger working volumes and more efficient assembly techniques for additive manufacturing. The integration of sensors and actuators into the fabrication process is essential for the development of active exoskeletons. Moreover, combining shape or topology optimization tools with additive manufacturing can lead to the production of lightweight structures without compromising mechanical performance.

- Conclusion

Additive manufacturing has transformed the production of orthoses, making personalized devices more accessible and cost-effective. By enabling the fabrication of complex, customized orthotic devices, AM has the potential to significantly improve patient outcomes and quality of life. While challenges remain, ongoing research and technological advancements promise a bright future for the use of additive manufacturing in orthotics.

If you have related needs, please feel free to contact us for more information or product support.

Reference

- Alqahtani, Mohammed S., et al. "A review on the use of additive manufacturing to produce lower limb orthoses." Progress in Additive Manufacturing 5.2 (2020): 85-94.

This article is for research use only. Do not use in any diagnostic or therapeutic application.

Lower Limb Fixation Series

Fig.1 Different additive manufacturing technologies: a vat photo-polymerisation, b material jetting, c material extrusion, d power bed fusion, e binder jetting, f sheet lamination, g direct energy deposition. (Alqahtani M. S., et al., 2020)

Fig.1 Different additive manufacturing technologies: a vat photo-polymerisation, b material jetting, c material extrusion, d power bed fusion, e binder jetting, f sheet lamination, g direct energy deposition. (Alqahtani M. S., et al., 2020)