If you are interested in products and services related to the research phase in this field, please contact for further inquiries.

The field of orthotics is undergoing a transformative shift with the advent of 3D printing technology. Traditional orthotics, while effective, often lack the customization necessary to address individual patient needs. This limitation is particularly pronounced in cervical orthotics, where comfort, fit, and functionality are paramount. The integration of 3D printing offers a solution that enhances patient outcomes by providing personalized, high-precision devices tailored to individual anatomies.

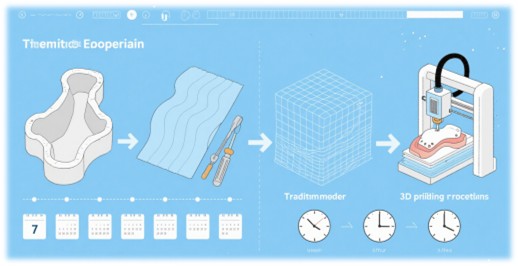

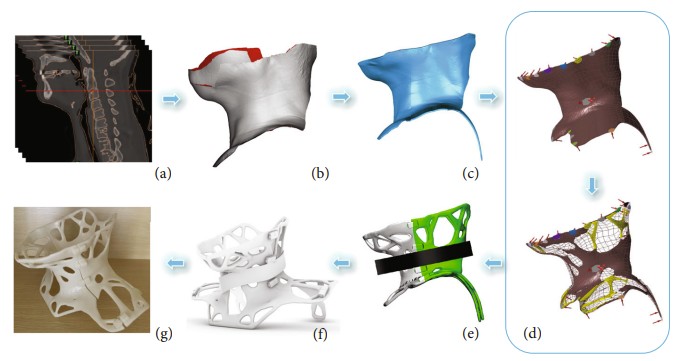

Fig.1 Schematic representation of design workflow and fabrication process of a custom orthosis. (Xu Y., et al., 2022)

Fig.1 Schematic representation of design workflow and fabrication process of a custom orthosis. (Xu Y., et al., 2022)

Traditional Cervical Orthotics: Limitations and Challenges

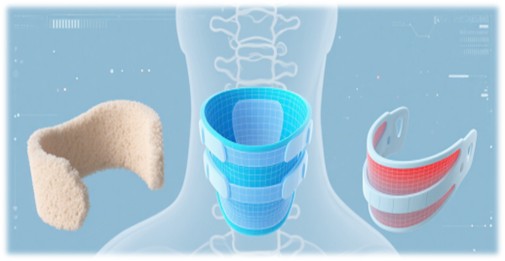

Traditional cervical orthotics are broadly categorized into three types: soft neck orthotics, padded mandibular and occipital supports with metal uprights, and cervical thoracic orthoses. These devices, though widely used, present several challenges. Soft neck orthotics, primarily composed of foam rubber, offer limited support and are often insufficient for severe injuries. Padded mandibular and occipital supports, while providing better support, are bulky and can cause discomfort. Cervical thoracic orthoses, designed for more severe cases, are rigid and can restrict patient movement significantly.

These traditional orthotics also face issues related to manufacturing time, cost, and customization. The process of creating plaster molds and thermoplastic plates is labor-intensive and time-consuming, often taking up to a week. Additionally, these methods lack the precision required to address individual patient needs, leading to discomfort and potential complications.

The Promise of 3D Printing in Orthotics

3D printing, also known as additive manufacturing, has emerged as a game-changing technology in the field of orthotics. This technology allows for the creation of complex structures with high precision, directly from 3D computer-aided design (CAD) files. The ability to customize orthotics to individual patient anatomies offers significant advantages over traditional methods.

Customization and Precision

3D printing enables the creation of orthotics that are precisely tailored to the patient's unique anatomy. By using patient-specific data, such as CT scans, orthotics can be designed to fit perfectly, reducing discomfort and improving functionality. This level of customization is particularly beneficial for cervical orthotics, where the fit must balance support with patient comfort.

Lightweight and Durable Materials

Modern 3D printing materials, such as durable and waterproof photosensitive resins, offer a lightweight yet robust alternative to traditional materials. These materials not only reduce the weight of the orthosis but also enhance its durability, making it suitable for long-term use.

Rapid Production

One of the most significant advantages of 3D printing is the rapid production time. Traditional orthotics can take up to a week to manufacture, whereas 3D printing can produce orthotics in a matter of hours. This speed allows for quicker patient turnaround times and the ability to make adjustments more efficiently.

Case Study: Personalized Cervical Fixation Orthosis

A recent study published in Applied Bionics and Biomechanics highlights the successful application of 3D printing in creating a personalized cervical fixation orthosis. The study involved a 53-year-old female patient who had undergone posterior cervical single-door open-door laminoplasty. The patient's cervical spine CT data were used to create a 3D model, which was then optimized for structural integrity and comfort.

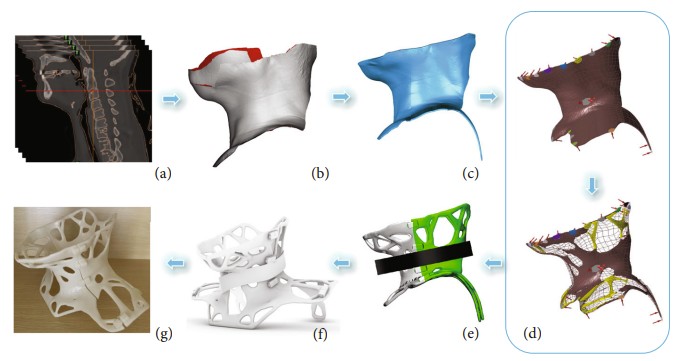

Data Collection and 3D Reconstruction

The patient's cervical spine was scanned using a 128-slice spiral CT scanner, and the data was imported into Mimics 21.0 software for 3D reconstruction. The resulting model provided a precise digital representation of the patient's cervical spine, forming the basis for the orthosis design.

Surface Fitting and Topology Optimization

The 3D model was further processed in Geomagic Studio 2013 to remove noise and spikes and to fit the surface smoothly. The optimized model was then imported into Altair Inspire Studio 2018 for topology optimization. Constraints and load forces were applied to simulate real-world conditions, ensuring the orthosis could withstand the necessary forces while maximizing stiffness and minimizing material usage.

Final Design and 3D Printing

The final orthosis design included features such as a hollow structure for ventilation, openings for wound care, and adjustable buckles for a secure fit. The design was printed using a durable and waterproof photosensitive resin, resulting in a lightweight orthosis weighing 477 grams. The entire printing process took approximately 4 hours and 34 minutes.

Patient Evaluation and Results

The patient wore the orthosis for varying durations, and her comfort was assessed using a detailed questionnaire. The results showed no significant discomfort, with only minor pressure on the bilateral scapulae. The orthosis effectively limited the cervical spine's range of motion, ensuring stability while allowing for some mobility. The patient reported high satisfaction with the orthosis's appearance, weight, and breathability.

Advantages of 3D Printed Orthotics

The study underscores several key advantages of 3D printed orthotics:

- Customization

3D printed orthotics are tailored to the patient's unique anatomy, ensuring a perfect fit and improved comfort. This level of customization is particularly beneficial for cervical orthotics, where the fit must balance support with patient comfort.

- Lightweight Design

The hollow structure of the orthosis reduces its weight, making it more comfortable to wear. This design also improves ventilation, reducing discomfort during prolonged use.

- Aesthetics

3D printed orthotics have an attractive appearance, which can be important for patient acceptance. The ability to customize the design allows for orthotics that are both functional and aesthetically pleasing.

- Functionality

The design allows for easy wound care and observation, crucial for postoperative recovery. The orthosis also includes features such as adjustable buckles for a secure fit, enhancing its functionality.

- Rapid Production

The 3D printing process significantly reduces production time compared to traditional methods. This speed allows for quicker patient turnaround times and the ability to make adjustments more efficiently.

Future Directions and Challenges

While the study demonstrates the potential of 3D printing in orthotics, there are still challenges to overcome. The cost of 3D printing materials and equipment can be prohibitive, although advancements in technology are gradually making these more affordable. Additionally, further research is needed to optimize printing materials and techniques for maximum durability and functionality.

Expanding the Patient Base

The next steps in this research include expanding the patient base to gather more comprehensive data on the orthosis's effectiveness and comfort. Long-term studies will also be necessary to assess the durability and wear patterns of 3D printed orthotics.

Advancements in Materials and Techniques

Ongoing research is focused on developing new materials and printing techniques that enhance the durability and functionality of 3D printed orthotics. These advancements will be crucial in making personalized orthotics more widely available and cost-effective.

Conclusion: A New Era in Orthotic Care

The integration of 3D printing technology in the field of orthotics marks a significant milestone in the development of personalized medical devices. The ability to create orthotics that are tailored to individual patient needs offers significant advantages in terms of comfort, functionality, and aesthetics. As 3D printing technology continues to advance, it holds the promise of transforming orthotic care, providing patients with better support and improved quality of life during their recovery journey.

The future of orthotics lies in the continued development and refinement of 3D printing technologies. With ongoing research and innovation, personalized orthotics could become the standard of care, offering patients tailored solutions that enhance their comfort and recovery outcomes.

If you have related needs, please feel free to contact us for more information or product support.

Reference

- Xu, Yangyang, et al. "Design of personalized cervical fixation orthosis based on 3D printing technology." Applied Bionics and Biomechanics 2022.1 (2022): 8243128.

This article is for research use only. Do not use in any diagnostic or therapeutic application.

Fig.1 Schematic representation of design workflow and fabrication process of a custom orthosis. (Xu Y., et al., 2022)

Fig.1 Schematic representation of design workflow and fabrication process of a custom orthosis. (Xu Y., et al., 2022)