If you are interested in products and services related to the research phase in this field, please contact for further inquiries.

Orthopedic external fixation has long been a cornerstone in the treatment of complex lower limb injuries. However, traditional external fixators often fall short in addressing the unique anatomical variations of individual patients, leading to suboptimal outcomes. The advent of additive manufacturing (AM) and advanced computational techniques has opened new avenues for creating customized external fixation devices that are tailored to individual patient needs. This article explores the latest advancements in this field, focusing on the integration of computer tomography (CT), computer-aided design (CAD), finite element analysis (FEA), and AM to produce lightweight, high-performance external fixators.

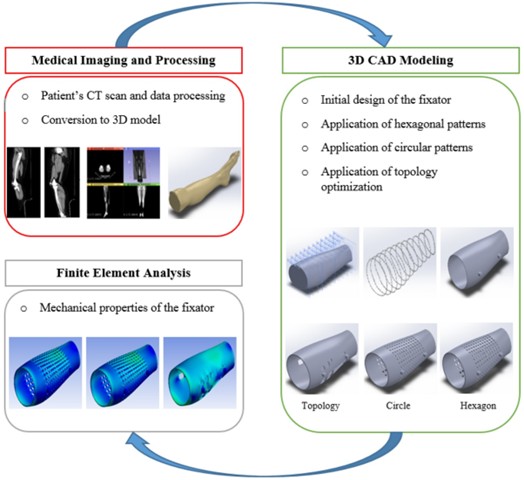

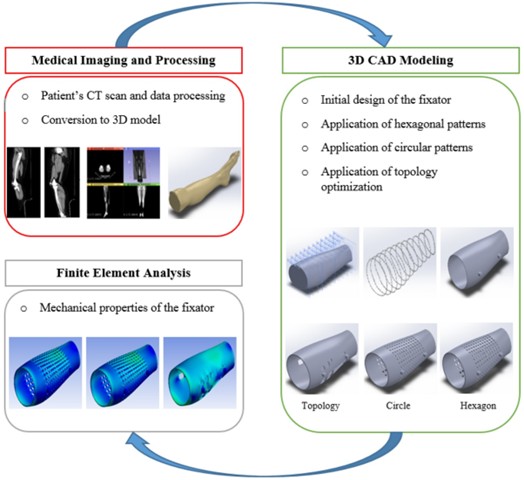

Fig.1 Enhancement of a customized external fixation apparatus tailored for lower limb injuries. (Alqahtani M. S., et al., 2021)

Fig.1 Enhancement of a customized external fixation apparatus tailored for lower limb injuries. (Alqahtani M. S., et al., 2021)

The Need for Customization in Orthopedic Fixation

Lower limb injuries, ranging from fractures to soft tissue damage, require precise and stable fixation to ensure proper healing. Traditional external fixators, while effective in many cases, are often bulky, heavy, and not tailored to the specific anatomy of the patient. This can lead to discomfort, prolonged recovery times, and potential complications such as infections and non-unions. The need for patient-specific external fixators has become increasingly evident, especially with the growing aging population and the rise in trauma incidents.

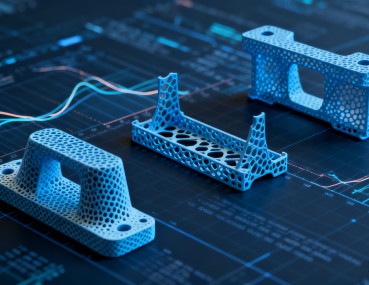

The Role of Additive Manufacturing in Orthopedics

Additive manufacturing, commonly known as 3D printing, has revolutionized the medical device industry. This technology allows for the creation of complex geometries that can be precisely tailored to individual patient anatomies. AM offers several advantages over traditional manufacturing methods, including the ability to produce lightweight, high-strength devices with intricate designs. The use of AM in orthopedics has already shown significant promise in the production of implants, prosthetics, and orthotics, and its application in external fixation devices is a natural progression.

Data Acquisition and Processing: The Foundation of Customization

The first step in creating a customized external fixation device is the acquisition of accurate anatomical data. Computer tomography (CT) imaging is the gold standard for capturing detailed 3D representations of the patient's limb. The CT data, typically in DICOM format, is then processed using specialized software to convert it into a format suitable for CAD modeling. This process involves converting the data into a Nearly Raw Raster Data (NRRD) file, which is then transformed into a 3D solid STereoLithography (STL) model. The STL model is subsequently refined in CAD software to correct any errors and remove unnecessary regions, resulting in a precise digital representation of the patient's limb.

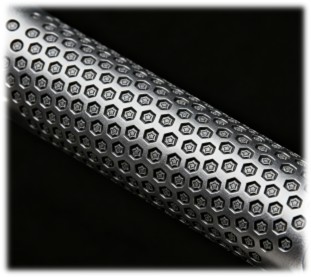

Design Techniques: Predefined Patterns vs. Topology Optimization

Two primary design techniques are used to create lightweight external fixators: predefined patterns and topology optimization. Predefined patterns involve the application of geometric shapes, such as circles and hexagons, to the middle section of the fixator. These patterns are designed to create a porous structure that reduces weight while maintaining structural integrity. In contrast, topology optimization is an automated process that removes excess material from the initial design, resulting in a lightweight structure with optimal mechanical performance. This method is particularly advantageous because it can automatically identify and eliminate redundant material without compromising the device's strength or stability.

Predefined Patterns: A Traditional Approach

Predefined patterns have been used for decades in the design of lightweight structures. In the context of external fixators, circular and hexagonal patterns are commonly applied to the middle section of the device. These patterns are designed to distribute stress evenly across the structure, reducing the risk of stress concentration and potential failure. Recent studies have shown that smaller, more densely packed patterns provide better mechanical properties, with the circular pattern showing the most promising results.

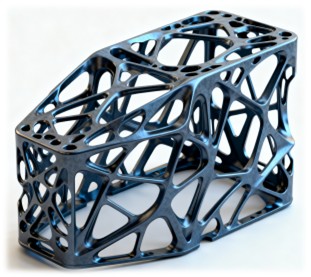

Topology Optimization: A Modern Solution

Topology optimization represents a significant advancement in the design of lightweight structures. This technique uses computational algorithms to remove excess material from the initial design, resulting in a structure that is both lightweight and mechanically optimized. The process begins with the creation of a solid model, which is then subjected to a series of optimization algorithms. The result is a complex, optimized structure that is tailored to the specific loading conditions and boundary constraints. In the context of external fixators, topology optimization has been shown to significantly reduce weight while maintaining or even enhancing mechanical performance.

Finite Element Analysis: Ensuring Mechanical Performance

Finite element analysis (FEA) is a critical tool in the design and evaluation of external fixation devices. This computational technique allows engineers to simulate the mechanical behavior of the device under various loading conditions, providing valuable insights into its performance. Key structural parameters such as stresses, displacements, strength, and stiffness can be evaluated using FEA. In recent studies, FEA has been used to compare the mechanical performance of external fixators designed with predefined patterns and those optimized using topology optimization. The results consistently show that topology-optimized fixators exhibit superior mechanical properties, with significantly higher strength and stiffness compared to their predefined pattern counterparts.

Experimental Design and Optimization

To further refine the design parameters of external fixators, researchers often employ experimental design techniques such as full factorial design of experiments. This method allows for the systematic investigation of multiple design factors, such as thickness, material, and design type, and their interactions. By conducting simulations under various conditions, researchers can identify the optimal combination of factors that maximize strength and stiffness while minimizing weight. Recent studies have shown that the optimal design parameters for a strong, stiff, and lightweight external fixator include a topology-optimized design made from polylactic acid (PLA) with a thickness of 4mm.

Convergence Analysis and Statistical Analysis

To ensure the accuracy and reliability of FEA simulations, researchers often perform convergence analysis. This process involves running simulations with varying mesh sizes to determine the most suitable mesh resolution. In the context of external fixators, convergence analysis has shown that an element size of 1mm provides the most accurate results. Additionally, statistical analysis techniques such as analysis of variance (ANOVA) and Pareto chart analysis are used to identify significant factors and interactions affecting the mechanical performance of the device. These analyses provide valuable insights into the design process, helping researchers make informed decisions and optimize the final product.

Future Directions and Clinical Implications

The integration of advanced imaging, computational design, and additive manufacturing technologies represents a significant step forward in the field of orthopedics. Customized external fixation devices offer several advantages over traditional devices, including improved patient comfort, reduced recovery times, and enhanced mechanical performance. As additive manufacturing continues to advance, the potential for creating personalized medical devices that meet specific patient needs becomes increasingly promising. Future research will focus on further optimizing design parameters, exploring new materials, and conducting clinical trials to validate the performance of these devices in real-world scenarios.

If you have related needs, please feel free to contact us for more information or product support.

Reference

- Alqahtani, Mohammed S., et al. "Optimization of a patient-specific external fixation device for lower limb injuries." Polymers 13.16 (2021): 2661.

This article is for research use only. Do not use in any diagnostic or therapeutic application.

Lower Limb Fixation Series

Fig.1 Enhancement of a customized external fixation apparatus tailored for lower limb injuries. (Alqahtani M. S., et al., 2021)

Fig.1 Enhancement of a customized external fixation apparatus tailored for lower limb injuries. (Alqahtani M. S., et al., 2021)