If you are interested in products and services related to the research phase in this field, please contact for further inquiries.

In the realm of medical devices, innovation often hinges on the delicate balance between affordability, accessibility, and functionality. The advent of open-source 3D printable forearm crutches marks a significant stride in this direction, promising a future where mobility aids are not only cost-effective but also highly customizable and environmentally sustainable. This article delves into the scientific underpinnings, design intricacies, and potential impact of this groundbreaking technology.

The Global Need for Affordable Mobility Aids

Mobility impairments affect a substantial portion of the global population, with over 10% of adults experiencing some form of mobility-related disability. As populations age, this number is projected to rise significantly. Conditions such as arthritis, chronic back pain, and injuries from accidents contribute to the growing demand for mobility aids. By 2060, nearly a quarter of the U.S. population will be 65 years or older, exacerbating the need for effective and affordable mobility solutions.

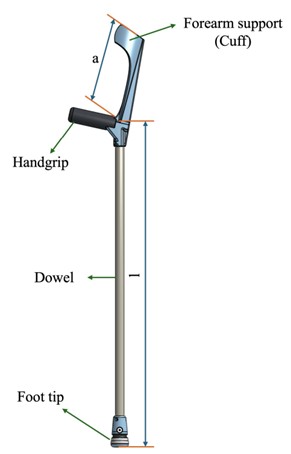

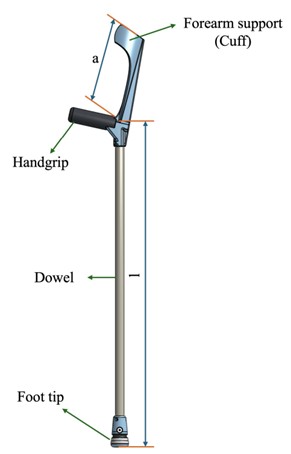

Fig.1 Dimensional measurements of assembled crutch. a) length of forearm 227mm, l) length of leg section 794mm. (Mottaghi M., et al., 2025)

Fig.1 Dimensional measurements of assembled crutch. a) length of forearm 227mm, l) length of leg section 794mm. (Mottaghi M., et al., 2025)

The Economic and Social Impact of Mobility Aids

The economic burden of mobility aids is a critical factor in their accessibility. Commercial crutches, canes, walkers, and wheelchairs are often priced out of reach for many individuals, particularly those in less developed regions or living in poverty. The high costs of these devices not only limit their availability but also contribute to social inequalities, as those without financial means are further marginalized. Addressing this challenge requires innovative solutions that balance affordability with functionality.

The Role of Digital Distributed Manufacturing

Digital distributed manufacturing, facilitated by 3D printing, offers a transformative approach to producing mobility aids. This technology leverages Computer Numerical Control (CNC) tools to create customizable products at a fraction of the cost of traditional manufacturing. The shift from prototyping to producing usable goods has democratized access to manufacturing, making it possible to produce affordable products locally. This revolution is further propelled by the proliferation of free and open-source hardware (FOSH), which provides consumers with the tools to create customized products at significantly reduced costs.

The Open-Source Forearm Crutch: Design and Materials

The open-source forearm crutch developed by researchers at Western University exemplifies the potential of digital distributed manufacturing. This crutch combines 3D printed joints with commercially available hardwood dowels, offering a sustainable and customizable solution. The design process incorporated rigorous load-bearing tests to meet the ISO 11334-1:2007 standard for walking aids, ensuring the crutch's durability and safety.

Ergonomic Design

The crutch features an ergonomic handle and cuff, designed to provide comfortable support for the forearm. The handle and cuff are integrated into a single 3D printed part, ensuring a secure fit and reducing the risk of lateral movement. This design not only enhances user comfort but also minimizes the potential for injury during prolonged use.

Sustainable Materials

The choice of materials is pivotal in the crutch's design. Hardwood dowels were selected for their sustainability, ease of availability, and compatibility with 3D printed components. Hardwood is a renewable resource known for its ability to absorb carbon during growth, offsetting some emissions associated with its processing. Additionally, the use of recycled plastics in the crutch's design further reduces its environmental impact, aligning with global efforts to minimize waste and promote sustainability.

Mechanical Testing and Performance

To ensure the crutch's safety and effectiveness, mechanical testing was conducted using an MTS hydraulic actuator. The crutch was subjected to static loading conditions as per the ISO 11334-1:2007 standard, which requires crutches to support a load of 1000N ±2% without breaking or deforming for a specified duration of 10 seconds. The results were remarkable, with the crutch demonstrating an average compressive load capacity of 1,516.3±169.9N, significantly exceeding the standard.

Load Capacity

The crutch's superior load capacity is a testament to its robust design. With an average capacity of 1,516.3±169.9N, the crutch can safely support users with body weights higher than the average weight of Canadian men (86.4kg) and women (72.1kg). This capacity ensures that the crutch is suitable for a broad range of users, providing a high degree of versatility and reliability.

Weight Reduction

The crutch's lightweight design is another significant advantage. Weighing just 0.612kg, the crutch is approximately 73% lighter than commercial crutches made of aluminum and plastic. This weight reduction not only promotes less labor-intensive use but also enhances ease of transport, making the crutch a practical solution for individuals with mobility impairments.

Customization and Personalization

One of the most compelling aspects of the open-source crutch is its customization potential. 3D printing allows for the production of crutches tailored to individual needs, ensuring a perfect fit for each user. The crutch's design can be adjusted to accommodate users of various heights, and the use of TPU thermoplastic feet and handle covers provides enhanced shock absorption and comfort during extended periods of use.

Cost-Effectiveness and Accessibility

The open-source crutch is a highly cost-effective solution, with a total production cost of CAD$35.31 using virgin plastic. This cost can be further reduced by using recycled plastics, making the crutch accessible to a broader range of individuals. The ability to produce these crutches locally using inexpensive desktop 3D printers ensures that they are not only affordable but also readily available, addressing the critical need for accessible mobility aids.

Future Improvements and Scalability

Despite its many advantages, the open-source crutch has some limitations. The high amount of plastic material required for 3D printing increases production time and environmental impact. Additionally, the crutch's design does not allow for on-the-go height adjustability. Future improvements could involve reducing the amount of plastic used, making the crutch more scalable and environmentally friendly.

Reducing Plastic Usage

Future iterations of the crutch could involve making the one-piece forearm out of two parts, reducing the amount of plastic used and decreasing production time. This would also make the parts small enough to fit on a wider range of 3D printers, enhancing the crutch's accessibility.

Height Adjustability

Developing a crutch with an adjustable height would make it suitable for multiple users and allow manufacturers to stock pre-assembled crutches that can be easily customized at the time of purchase. One potential approach is to add a telescoping mechanism into the wooden dowel, enabling height adjustments during use.

Conclusion

The open-source 3D printable forearm crutch represents a significant advancement in the field of mobility aids. With its superior load capacity, lightweight design, and cost-effectiveness, this crutch has the potential to transform the lives of individuals with mobility impairments. As technology continues to evolve, the future of mobility aids looks promising, with the potential for even greater customization and scalability.

If you have related needs, please feel free to contact us for more information or product support.

Reference

- Mottaghi, Maryam, et al. "Open-source 3D printable forearm crutch." PloS one 20.2 (2025): e0318987.

This article is for research use only. Do not use in any diagnostic or therapeutic application.

Crutches Series

Fig.1 Dimensional measurements of assembled crutch. a) length of forearm 227mm, l) length of leg section 794mm. (Mottaghi M., et al., 2025)

Fig.1 Dimensional measurements of assembled crutch. a) length of forearm 227mm, l) length of leg section 794mm. (Mottaghi M., et al., 2025)