If you are interested in products and services related to the research phase in this field, please contact for further inquiries.

3D printing, also known as additive manufacturing (AM), has revolutionized the healthcare industry by enabling the creation of highly customized medical devices and materials. This technology leverages computer-aided design (CAD) software and imaging data from computed tomography (CT) and magnetic resonance imaging (MRI) to produce patient-specific anatomical models, surgical guides, and implants with unparalleled precision. The global 3D printing market in healthcare is projected to grow significantly, driven by the increasing demand for personalized medical solutions and the expiration of key patents that have made 3D printing more accessible and cost-effective.

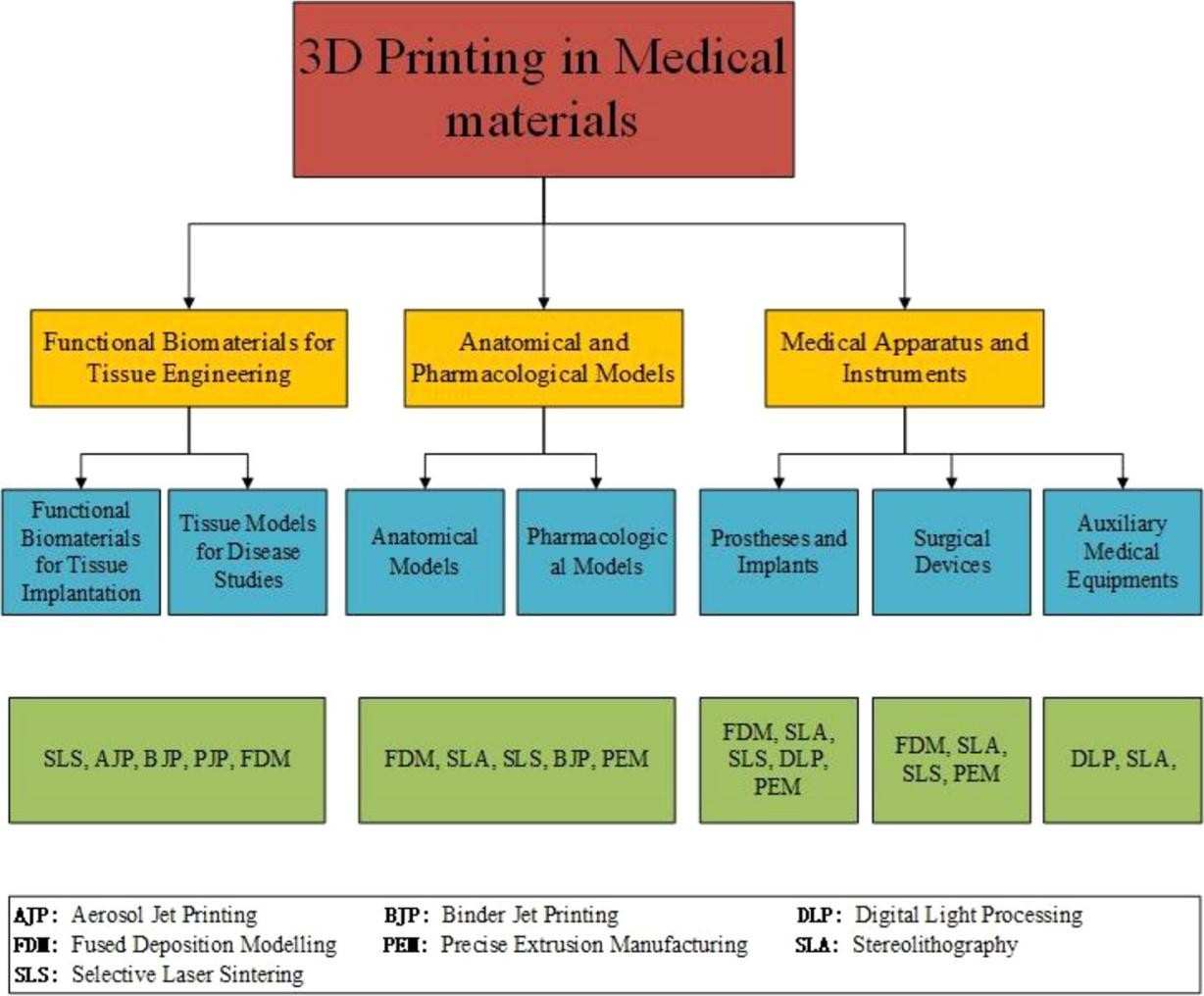

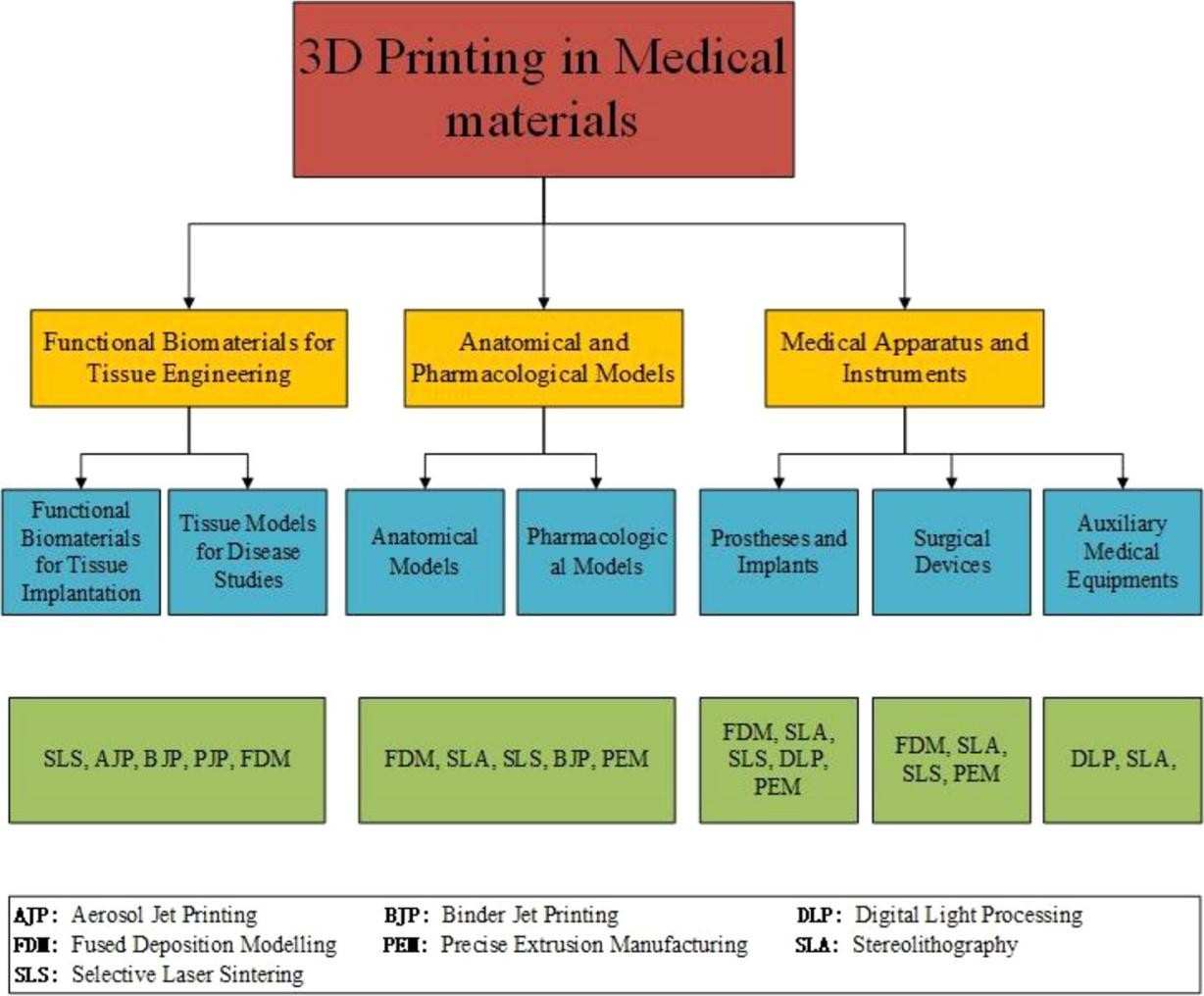

Fig.1 Progressive 3d printing technology and its application in medical materials. (Fan D., et al., 2020)

Fig.1 Progressive 3d printing technology and its application in medical materials. (Fan D., et al., 2020)

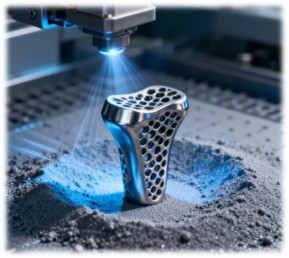

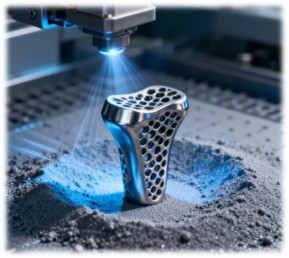

Powder-Based Printing Techniques

Powder-based 3D printing is a versatile technique that excels in creating complex structures with customizable external shapes, internal architectures, and porosities. This method includes several sub-techniques such as selective laser sintering (SLS), selective laser melting (SLM), direct metal laser sintering (DMLS), and electron beam melting (EBM). SLS and DMLS use lasers to bind powder particles layer by layer, while SLM and EBM fully melt the powder to produce fully dense parts with superior mechanical properties. These techniques are particularly useful for creating metal implants and prosthetics with high precision and strength.

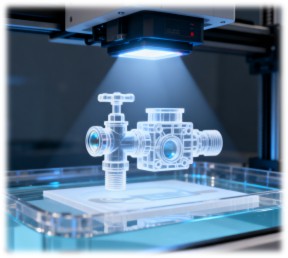

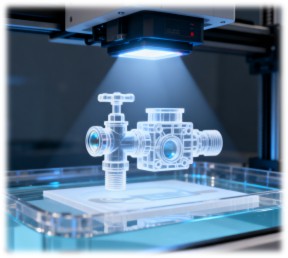

Vat Polymerization-Based Printing

Vat polymerization-based printing relies on light-curing resin materials and selective hardening through polymerization. This technique is widely used for creating complex devices with functional parts such as valves, lenses, and fluidic interconnects. Digital light processing (DLP) and stereolithography (SLA) are common processes that use light to selectively cure the resin, resulting in high-resolution and detailed parts. Multiphoton polymerization (MPP) further enhances precision by using a femtosecond laser to cure the resin in multiple directions, allowing for the creation of highly complex structures without layer-by-layer fabrication.

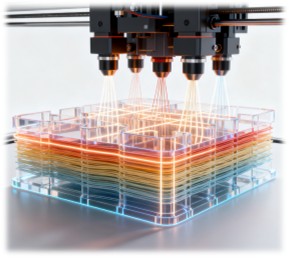

Droplet-Based Printing

Droplet-based printing, also known as material jetting, involves ejecting droplets of liquid materials and selectively polymerizing them using UV light. This technique includes aerosol jet printing (AJP), binder jet printing (BJP), and poly jet printing (PJP). AJP uses aerosolized materials carried by a gas to deposit droplets onto a substrate, making it suitable for bioprinting applications. BJP uses a binder to join powder particles, while PJP deposits polymer resin droplets that are immediately cured by UV light, allowing for the creation of high-resolution, detailed structures.

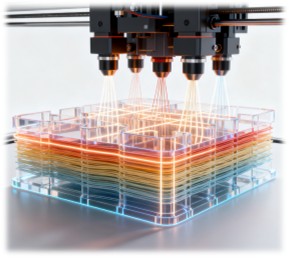

Extrusion-Based Printing

Extrusion-based printing, commonly known as fused deposition modeling (FDM), involves extruding thermoplastic or composite materials through a heated nozzle. Layers are deposited and solidified as the nozzle moves horizontally and vertically. This technique is widely used in metal printing, polymer printing, and bioprinting. Precision extrusion deposition (PED) and precise extrusion manufacturing (PEM) further enhance the precision and quality of printed parts, making them suitable for high-resolution applications. Multiple heads deposition extrusion (MHDS) uses multiple extrusion heads to deposit materials simultaneously, increasing the speed and complexity of the printing process.

Functional Biomaterials for Tissue Engineering

Tissue engineering aims to create functional tissues and organs for transplantation. 3D printing has played a crucial role in this area by enabling the fabrication of tissue scaffolds with high precision and customization. These scaffolds provide structural support for cell attachment, proliferation, and migration, making them essential for tissue regeneration. Tissue scaffolds are created using various 3D printing techniques, including vat polymerization, SLS, BJP, and FDM. Bioprinting involves printing with living cells mixed in bioinks or gels, allowing for the creation of complex tissue structures with high cell density.

Anatomical and Pharmacological Models

3D printed anatomical models have become invaluable tools in medical education and surgical planning. These models provide detailed representations of human anatomy, allowing for better visualization and understanding of complex structures. Pharmacological models are used for drug testing and validation, offering a more accurate and efficient alternative to traditional animal models. Tissue models of various organs, such as the liver, skin, and tumor, have been developed using 3D printing. These models are used for studying disease mechanisms, drug screening, and preclinical therapy evaluation. For example, 3D printed liver models have been used for drug toxicity testing, while 3D printed skin models have been used to study wound healing and nanoparticle toxicity.

Medical Apparatus and Instruments

3D printing has also revolutionized the production of medical apparatus and instruments. Customized surgical guides, implants, and prosthetics can now be manufactured with high precision and efficiency, improving patient outcomes and reducing costs. Prostheses and implants offer several advantages over traditional methods. They can be customized to fit the patient's anatomy perfectly, reducing the risk of complications and improving long-term stability. Powder-based 3D printing techniques, such as SLM and EBM, are widely used for creating metal implants with excellent mechanical properties. In maxillofacial and craniofacial surgeries, 3D printing techniques allow for the creation of patient-customized prostheses with high precision. Cardiac diseases have also benefited from 3D printing, with various techniques used for advanced visualization, diagnosis, surgical planning, and education.

Conclusion

3D printing has emerged as a transformative technology in the healthcare industry, offering unparalleled precision, customization, and efficiency in the production of medical materials. From tissue engineering to the creation of complex medical devices, 3D printing is paving the way for innovative solutions that were once thought impossible. As the technology continues to advance and become more accessible, it is poised to revolutionize healthcare by improving patient outcomes, reducing costs, and accelerating the development of new treatments and therapies.

If you have related needs, please feel free to contact us for more information or product support.

Reference

- Fan, Daoyang, et al. "Progressive 3D printing technology and its application in medical materials." Frontiers in pharmacology 11 (2020): 122.

This article is for research use only. Do not use in any diagnostic or therapeutic application.

Fig.1 Progressive 3d printing technology and its application in medical materials. (Fan D., et al., 2020)

Fig.1 Progressive 3d printing technology and its application in medical materials. (Fan D., et al., 2020)