If you are interested in products and services related to the research phase in this field, please contact for further inquiries.

Additive manufacturing (AM), commonly known as 3D printing, has revolutionized various industries, and orthopedics is no exception. Traditional orthopedic treatments, particularly the use of custom-made splints, have long been a cornerstone in fracture management. However, these methods have significant drawbacks, including lengthy production times, discomfort for patients, and environmental waste. The advent of AM technology offers a promising alternative, enabling the creation of personalized, efficient, and sustainable orthopedic products. This article delves into the design and development of a 3D-printed arm splint, exploring the materials, design considerations, manufacturing process, and potential benefits of this innovative approach.

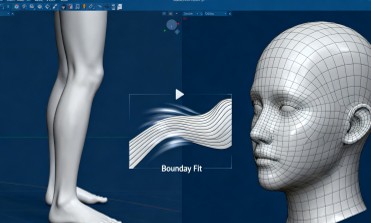

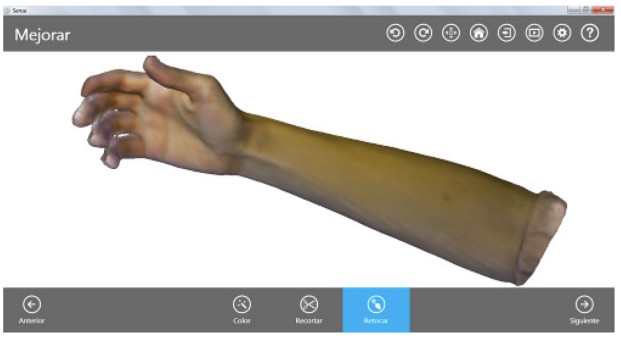

Fig.1 The arm after the Sense digitalization. (Blaya F., et al., 2018)

Fig.1 The arm after the Sense digitalization. (Blaya F., et al., 2018)

Limitations of Traditional Orthopedic Splints

Traditional splints and casts have been used for centuries to immobilize and support fractured limbs. While effective, they come with several challenges. Conventional arm splints are often heavy, leading to discomfort and potential pain in the neck and back. They restrict movement, causing muscle atrophy in the immobilized limb. Traditional casts are not breathable, leading to excessive sweating, poor hygiene, and skin issues such as allergies and itching. The closed nature of these casts also means that patients cannot easily monitor the healing process or apply physiotherapeutic treatments during the immobilization period. Furthermore, the non-recyclability of traditional casts contributes to significant waste, with an estimated 670,000 kg of waste generated annually from orthopedic casts in the United States alone.

Advantages of Additive Manufacturing in Orthopedics

AM technology offers several advantages over traditional manufacturing methods. It allows for the creation of complex, customized designs with high precision and reduced production times. By using 3D printing, it is possible to create splints that are tailored to the specific anatomy of a patient's limb, ensuring a perfect fit and increased comfort. Additionally, 3D-printed splints can be designed with openings and ventilation holes, allowing for better hygiene and the application of therapeutic techniques during the immobilization period. The use of biocompatible and recyclable materials further enhances the sustainability and environmental impact of these devices.

Materials Selection for 3D-Printed Arm Splints

The choice of material is crucial in the development of 3D-printed orthopedic devices. Polycarbonate is often selected for its biocompatibility, recyclability, and mechanical properties. It is lightweight, impermeable, and resistant to UV rays and fire, making it an ideal material for orthopedic applications. Additionally, it does not interfere with X-rays, allowing for accurate diagnostic imaging. For prototyping purposes, polylactic acid (PLA) is commonly used due to its availability, biodegradability, and similar manufacturing properties to polycarbonate.

Design Considerations for 3D-Printed Arm Splints

The design of a 3D-printed arm splint must address several key considerations to ensure optimal functionality and patient comfort. The splint features aesthetic and functional openings that allow for ventilation, washing, and visual control of the affected area. These openings also facilitate the application of muscle electrostimulation and various physiotherapy techniques, such as iontophoresis, sonotherapy, laser therapy, magnet therapy, and hydrotherapy. The splint's organic shape is designed to be more hygienic and comfortable than traditional geometric shapes, avoiding deposits and facilitating cleaning. The rubber button closure system provides a secure, easy-to-use, and detachable solution, allowing for occasional removal of the splint for medical reviews.

Manufacturing Process of 3D-Printed Arm Splints

The manufacturing process of a 3D-printed arm splint involves three main steps: three-dimensional digitalization, 3D modeling, and additive manufacturing.

Three-Dimensional Digitalization

The first step in creating the splint is the digitalization of the patient's limb using a 3D scanner. In a recent study, the forearm and right hand of a 20-year-old woman were scanned using a Sense scanner. The scanner captures a detailed 3D model of the limb, which is then processed to remove noise and limit the area of interest. This digital model serves as the basis for the splint design, ensuring a perfect fit and customization to the patient's anatomy.

3D Modeling

The digital model of the limb is then imported into a CAD program, such as Geomagic® DesignX, for further processing and design. A mesh surface of the arm is generated, and splines are used to create a detailed grid that adapts to the limb's shape. The Boundary Fit tool is then used to generate a surface between the splines, creating a smooth, organic shape for the splint. This surface is further refined in Rhinoceros® 5 to address complex areas, such as the thumb. The final surface is then offset to create a solid model of the splint, with openings and holes added for functionality and aesthetics.

Additive Manufacturing

The final step involves 3D printing the splint using a fused deposition manufacturing (FDM) printer. The prototype was printed using PLA, with the model scaled down by 40% to fit within the printer's volume. The printing parameters, such as layer height, print density, and temperature, are carefully selected to ensure optimal print quality and material properties. The resulting prototype is a lightweight, breathable, and customizable splint that fits snugly on the patient's arm.

Results and Potential Benefits

The study successfully demonstrated the feasibility of creating a 3D-printed arm splint using additive manufacturing technology. The prototype splint exhibited several advantages over traditional casts, including improved hygiene, reduced weight, and enhanced comfort. The design allowed for ventilation and the application of therapeutic techniques, potentially accelerating the healing process and improving patient outcomes. Additionally, the use of recyclable materials addressed the environmental concerns associated with traditional orthopedic casts.

Future Directions and Innovations

The potential applications of 3D-printed orthopedic devices extend beyond arm splints. The principles and techniques demonstrated in this study could be applied to other types of orthopedic supports, such as leg braces, spinal supports, and joint immobilizers. The customization offered by 3D printing could also be extended to include personalized designs that incorporate patient preferences and aesthetic considerations, potentially improving patient compliance and satisfaction.

Further research and development could focus on optimizing the materials and printing processes to enhance the mechanical properties and durability of the splints. Studies comparing the effectiveness of 3D-printed splints to traditional casts in clinical settings could provide valuable insights into the benefits and limitations of this technology. Additionally, the integration of smart materials and sensors into 3D-printed orthopedic devices could enable real-time monitoring of the healing process, providing valuable data to healthcare providers and improving patient outcomes.

Conclusion

The advent of additive manufacturing technology has opened new horizons in the field of orthopedics. The study presented here demonstrates the potential of 3D printing to create customized, functional, and sustainable orthopedic devices that address the limitations of traditional casts. By improving patient comfort, hygiene, and the ability to apply therapeutic techniques during the immobilization period, 3D-printed splints have the potential to significantly enhance the quality of life for patients with fractures. As this technology continues to evolve, it holds the promise of transforming orthopedic care and contributing to a more sustainable and patient-centered approach to fracture treatment.

If you have related needs, please feel free to contact us for more information or product support.

Reference

- Blaya, Fernando, et al. "Design of an orthopedic product by using additive manufacturing technology: the arm splint." Journal of medical Systems 42.3 (2018): 54.

This article is for research use only. Do not use in any diagnostic or therapeutic application.

Arm Fixation Series

Fig.1 The arm after the Sense digitalization. (Blaya F., et al., 2018)

Fig.1 The arm after the Sense digitalization. (Blaya F., et al., 2018)