If you are interested in products and services related to the research phase in this field, please contact for further inquiries.

The advent of fully automated systems for the production of medical isotopes marks a significant leap forward in the field of radiopharmaceuticals. Traditionally, the production of isotopes such as Zirconium-89 (89Zr) has been a labor-intensive process fraught with challenges related to radiation exposure, scalability, and consistency. However, recent advancements by researchers at the University of Manchester have introduced an automated system that leverages cutting-edge technologies like 3D printing, computer-controlled software, and advanced cooling mechanisms to streamline the production process. This system not only enhances safety and efficiency but also paves the way for large-scale, cost-effective radiopharmaceutical production.

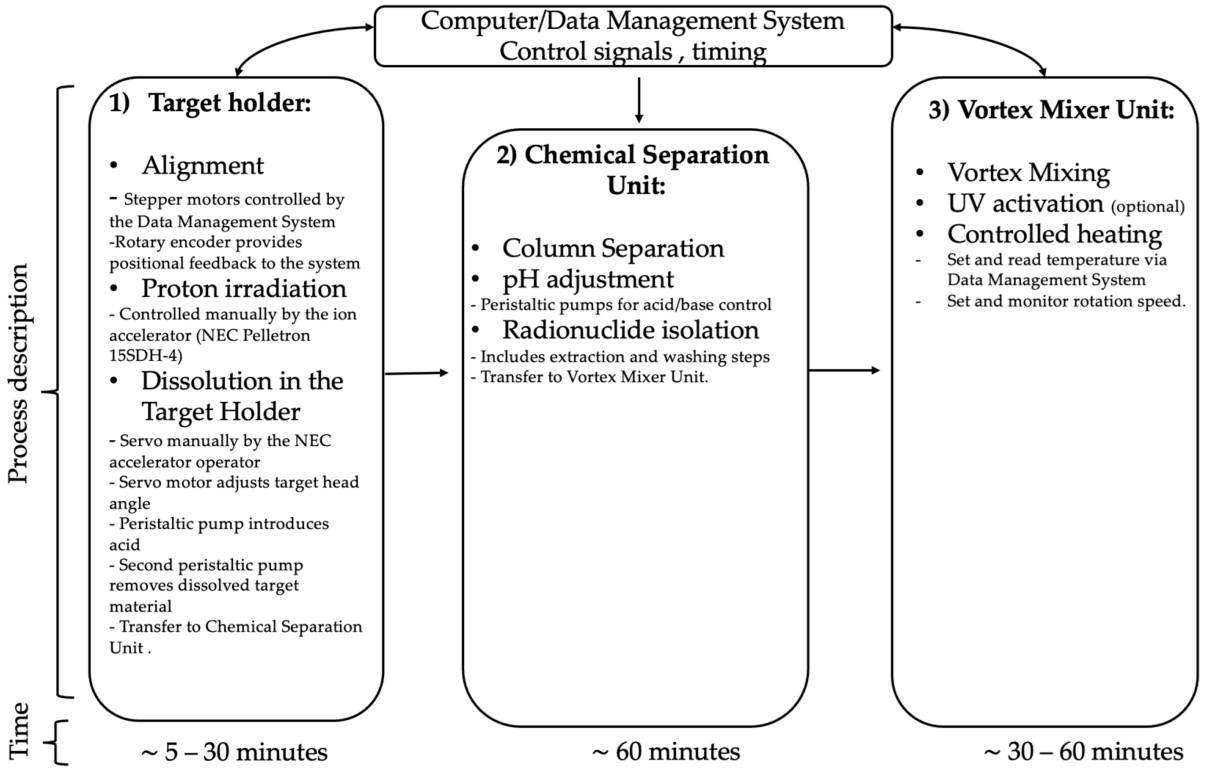

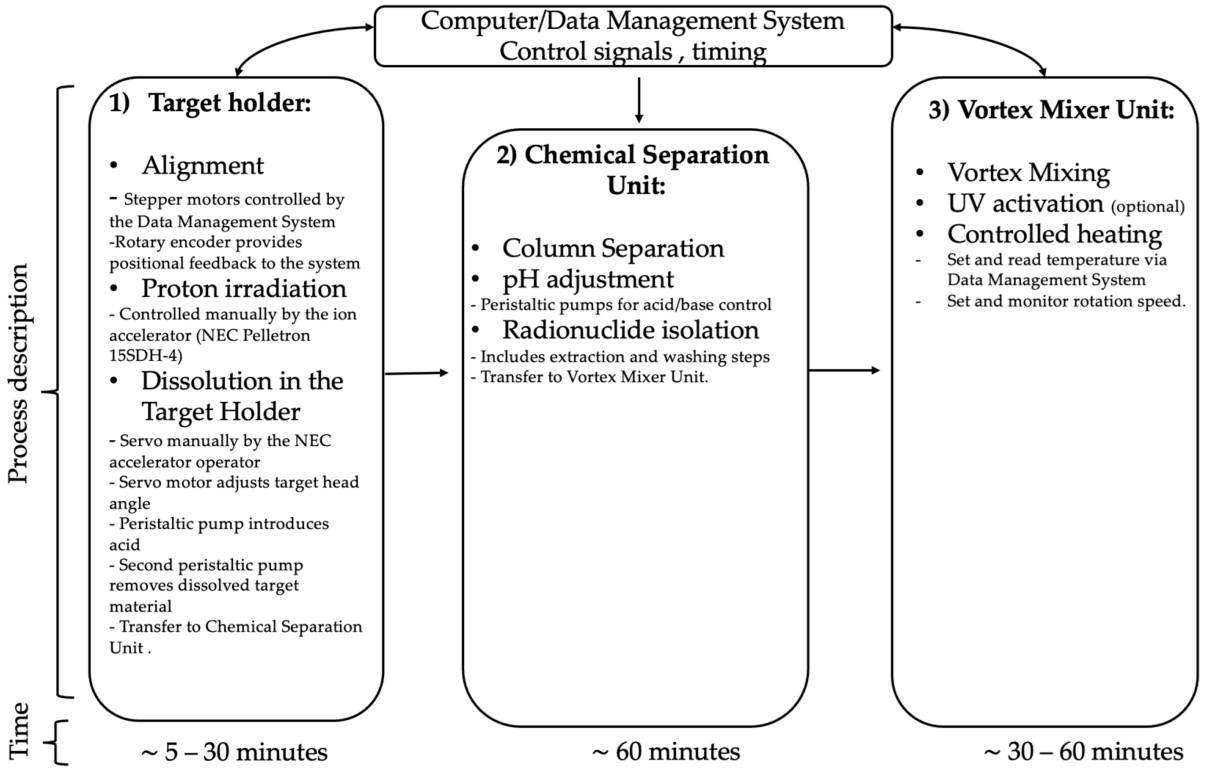

Fig.1 Automated radionuclide production process showing the target holder, chemical separation unit, and vortex mixer unit. (Hussain A. Y. M., et al., 2025)

Fig.1 Automated radionuclide production process showing the target holder, chemical separation unit, and vortex mixer unit. (Hussain A. Y. M., et al., 2025)

The Significance of Zirconium-89 in Medical Imaging

Zirconium-89 (89Zr) is a radionuclide with a half-life of 78.41 hours, making it highly suitable for immune-PET imaging. Its average positron energy (396.9 keV) and maximum positron energy (897 keV) allow for high-resolution imaging comparable to that achieved with other radionuclides like 64Cu and 18F. This makes 89Zr particularly useful for imaging monoclonal antibodies (mAbs) and immunoglobulin fragments, which are crucial in cancer diagnostics and therapy. Despite its potential, the production of 89Zr has been hindered by the lack of automated systems, leading to inefficiencies and increased radiation exposure for workers.

The Need for Automation in Radiopharmaceutical Production

Manual production of radiopharmaceuticals involves several steps, including target irradiation, chemical separation, and purification. Each of these steps exposes workers to radiation and increases the risk of contamination and human error. Moreover, manual processes are time-consuming and not easily scalable, limiting the availability of radiopharmaceuticals for widespread clinical use. The development of automated systems is therefore essential to improve efficiency, reduce radiation exposure, and ensure the reproducibility and purity of the final product.

Design and Construction of the Automated System

Target Holder and Translator

The foundation of the automated system is a 3D-printed target holder designed using computer-aided design (CAD) software. This holder, made from polypropylene, is both lightweight and resistant to the acids used in the dissolution process. The target holder consists of a bottom plate and a top plate, each with dimensions of 108 mm × 108 mm and a thickness of 20 mm. The bottom plate is designed to accommodate a CPU chiller, which cools the target during irradiation. The top plate features a conical structure that faces the ion beam and includes pathways for chemical reagents and helium gas. The helium gas pathway is crucial for cooling the top surface of the target and preventing unwanted reactions with the air.

A tantalum sheet is used to protect the aluminum of the CPU chiller from acid during the dissolution phase and to hold the metal target. The target holder is connected to a repurposed 3D printer, which serves as an X-Y translator, allowing automated alignment of the target before irradiation. The entire assembly is controlled by an Arduino board, enabling precise movement and orientation of the target holder.

Chemical Separation Unit

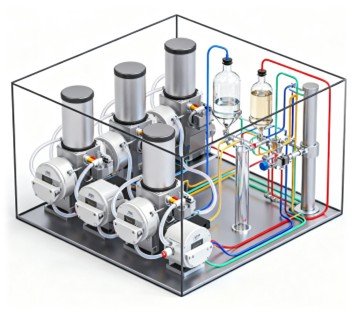

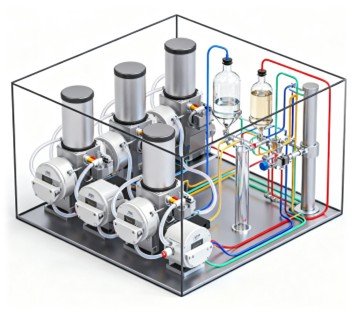

The chemical separation unit is a compact, automated system designed to fit into a 10 cm × 10 cm × 10 cm cube. This unit is responsible for the automated separation and purification of 89Zr from the irradiated target. It comprises six peristaltic pumps, a reaction vial, and two vials for the final product and waste liquids. The unit uses a commercial hydroxamate resin (ZR Resin) to separate 89Zr from yttrium (Y) with high efficiency. The entire process is controlled by an Arduino system, ensuring precise and consistent operation.

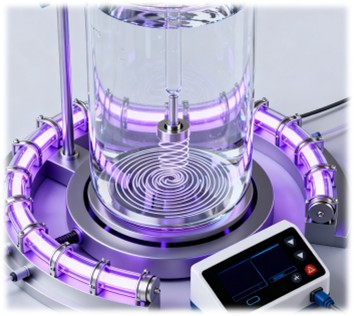

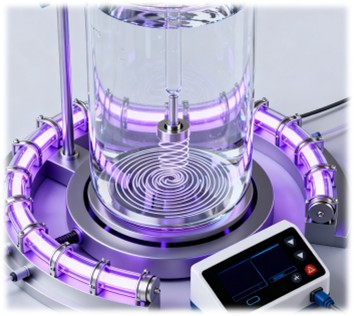

Photolabelling, Vortex Mixing, and Controlled Heating Unit

The photolabelling unit integrates vortex mixing, UV activation, and controlled heating to enhance labelling efficiency. This unit is designed to label antibodies with radioactive substances, a critical step in the production of radiopharmaceuticals. The core of the unit is a custom-designed glass beaker (reaction vessel) that supports each function with carefully integrated components. The vortex mixer and heater provide efficient mixing and temperature control, while the UV lights facilitate the photolabelling process. The entire unit is automated and managed through an electronic board controlled by Python-based software.

Experimental Methods and Results

- Irradiation Process

The nuclear reaction 89Y (p,n) 89Zr was used to produce 89Zr. A 5-MV tandem ion accelerator (NEC Pelletron 15SDH-4) was employed for irradiation, with the proton energy kept below 13 MeV to minimize the production of long-lived contaminants like 88Zr. The target, a 12-mm 89Y disc, was irradiated for a total of 30 minutes, producing 89Zr via the 89Y (p,n) 89Zr reaction. The target was cooled using chilled water and helium gas to maintain thermal stability during irradiation.

Thermal cameras and thermocouples were used to monitor the temperature during irradiation, ensuring that the target remained within a safe temperature range. The results showed that the target holder design effectively managed heat, with temperatures remaining below 40°C across the entire Y-foil. This demonstrated the system's capability to handle higher beam currents, enabling the production of approximately 50 GBq/h of 89Zr.

- Zr/Y Separation

The separation of Zr from Y was tested using a simulant solution with a Zr:Y atom ratio of 9:500. The ZR resin was used to separate Zr from Y, with the process optimized for high efficiency and purity. The results showed that no yttrium was found in the eluted zirconium fractions, even though yttrium was present in a significant excess ratio to zirconium. This demonstrated the effectiveness of the ZR resin in separating 89Zr from 89Y, even in complex mixtures.

- Photolabelling, Vortex Mixing, and Controlled Heating

The photolabelling unit was tested using aqueous solutions and dilute mineral acids. The results showed that the unit successfully integrated vortex mixing, controlled heating, and photolabelling, ensuring precise control over reaction conditions. The UV photolabelling setup functioned optimally, with three Luminus UV-C High Power Starboards providing direct UV irradiation to the reaction vessel. The cooling system maintained stable thermal conditions during UV exposure, preventing overheating and ensuring reproducible labelling.

Discussion

Advantages of the Automated System

The automated system offers several advantages over traditional manual methods. Firstly, it significantly reduces radiation exposure for workers by eliminating the need for manual handling of radioactive materials. Secondly, the system enhances efficiency and reproducibility by automating the entire production process, from target irradiation to chemical separation and photolabelling. Thirdly, the use of 3D printing and low-cost components makes the system highly adaptable and cost-effective, making it accessible to a broader range of research and clinical settings

Future Directions

The development of this automated system represents a significant step forward in the field of radiopharmaceutical production. Future work will focus on further optimizing the system for higher throughput and improved purity. Additionally, the system will be expanded to produce other medical isotopes, such as copper and scandium, demonstrating its versatility and potential for widespread clinical applications. The integration of advanced technologies such as machine learning and artificial intelligence could further enhance the system's capabilities, enabling real-time monitoring and optimization of the production process.

Conclusion

The fully automated system for medical isotope production developed by the University of Manchester researchers represents a revolutionary advancement in the field of radiopharmaceuticals. By integrating advanced technologies such as 3D printing, computer-controlled software, and efficient cooling mechanisms, this system addresses the challenges of manual production, enhancing safety, efficiency, and reproducibility. The successful demonstration of the system's capabilities in producing purified 89Zr paves the way for large-scale, cost-effective radiopharmaceutical production, promising to transform the landscape of medical imaging and therapy.

If you have related needs, please feel free to contact us for more information or product support.

Reference

- Hussain, Abdulaziz Yahya M., et al. "Apparatus and Experiments Towards Fully Automated Medical Isotope Production Using an Ion Beam Accelerator." Instruments 9.3 (2025): 18.

This article is for research use only. Do not use in any diagnostic or therapeutic application.

Fig.1 Automated radionuclide production process showing the target holder, chemical separation unit, and vortex mixer unit. (Hussain A. Y. M., et al., 2025)

Fig.1 Automated radionuclide production process showing the target holder, chemical separation unit, and vortex mixer unit. (Hussain A. Y. M., et al., 2025)